Thermography machines

- business cards - brochures - business cards

- wedding cards - labels - Christmas and New Year greeting cards

- postcards - gift wrappers - envelopes

- writing paper - soft book covers

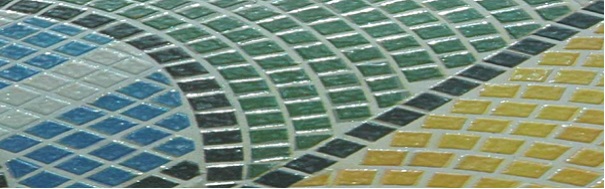

line strength 11-30 points grain 614

line strength 27-42 points grain 611

line strength 36-72 points grain size 609

special Braille size 607 and other spec.

Puff special embossed effects

Taking into account the varying grain size of the powders, the printer must be aware that the quality of work will vary according to the use of different originals with respect to line strength. If the document contains multiple types of lines, the printer must choose the appropriate compromise. The granularity of the 611 or 609 powder used with the 8 point font will overflow the edges and fill the letter blanks as if using too much heat. When using uppercase powder 614 such as point 24 of the bold type, the dimpled work will be similar to having been done without sufficient temperature.

Thermographer S-6 a S-12

sheets hand feed A6 - A3

Thermography machines HP-12, HP-15 a HP20

automatic thermography processing for sheets A6 to B3

Thermography machines SE-20, SE-30 a SE-40

automatic thermography processing

SE Series large format thermographic machines are available in 20", 30" and 40" ( 500, 760 and 1016 mm) widths. The SE series of thermographic machines is currently the most versatile device in its category in the world.

If you are using a large format and appreciate high productivity, long life and maximum energy savings, we are confident that you will be satisfied

- Three independently electronically controlled dual zone heat zones.

- Loading conveyor controlled independently of the heating and cooling conveyors using two DC motors.

- Durable drive system based on toothed wedge drives, drive chain and self-aligning external mounted bearings for easy access.

- High performance double cage cooling.

- Vacuum hold section of cooled sheets to increase cooling efficiency and reduce sheet curl.

- The cooling section is height adjustable in many positions.

- Self-cleaning sieve conveyor in cooling and heating section.

- Adjustable height of the heating section in many positions.